38*38*25mm OEM Fiberglass Reinforced FRP Gully Grating Plastic Floor Grating

38*38*25mm OEM Fiberglass Reinforced FRP Gully Grating Plastic Floor Grating FRP Molded grating is manufactured by layin

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | 002 |

| After-sales Service | Online |

| Warranty | 1year |

| Customized | Customized |

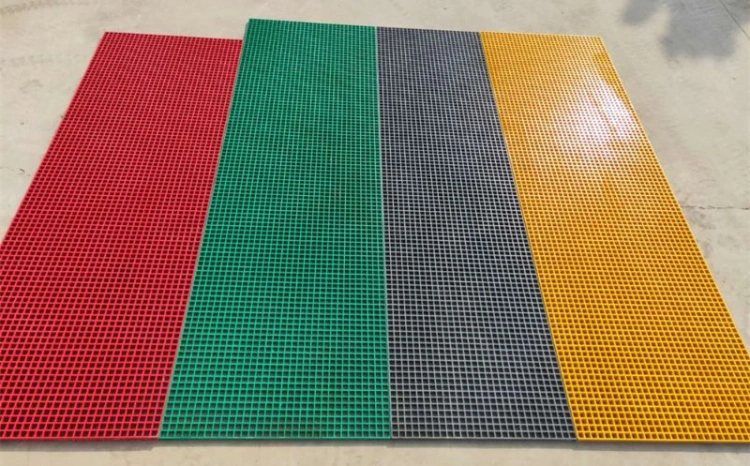

| Color | Multi-Color |

| Surface Treatment | Finished |

| Forming Way | Blow Molding |

| Shape | Square |

| Type | Flat |

| Material | GRP, FRP |

| Grating Color | Yellow, Red, Green, Blue, White and etc |

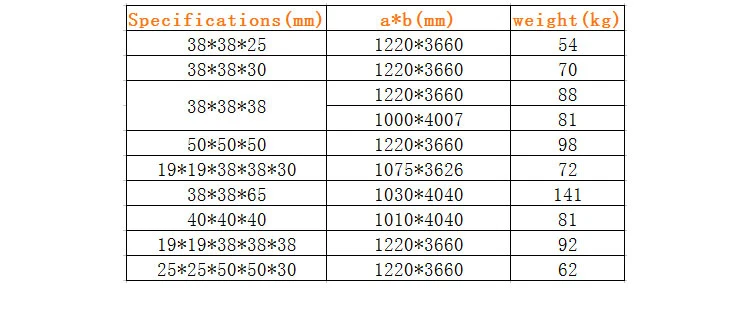

| Thickness | 25, 30, 38, 50mm |

| Usage | Environmental Protection, Industral, Walkways, etc |

| Technique | Molded Gratng From Mould |

| Product Categories | FRP Grating |

| Certificate | ISO9001, ABS, Dnv |

| Surface | Smooth, Gritted, Concave or Embeded Gritted |

| Transport Package | Pallet |

| Specification | 1220*3660mm, 1000*4007mm |

| Trademark | LT |

| Origin | China |

| HS Code | 3926909090 |

| Production Capacity | 100000000/Year |

Product Description

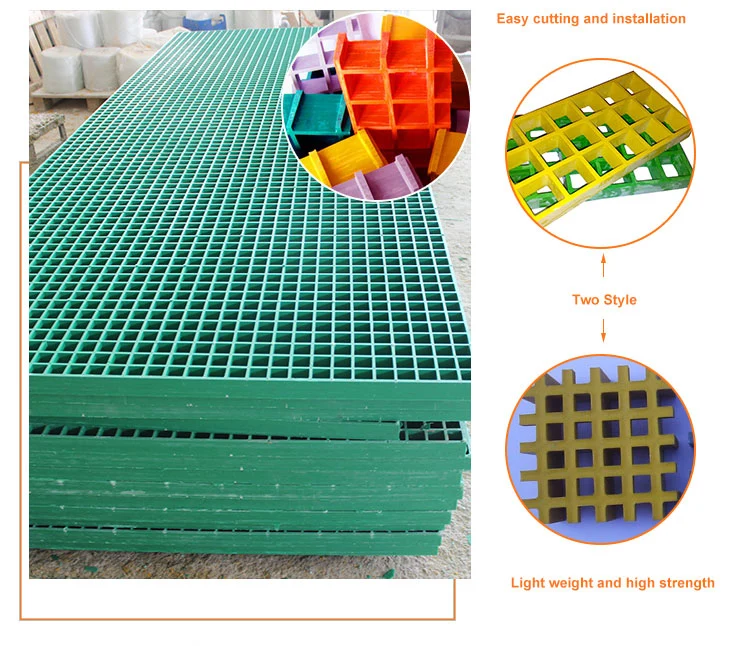

38*38*25mm OEM Fiberglass Reinforced FRP Gully Grating Plastic Floor Grating

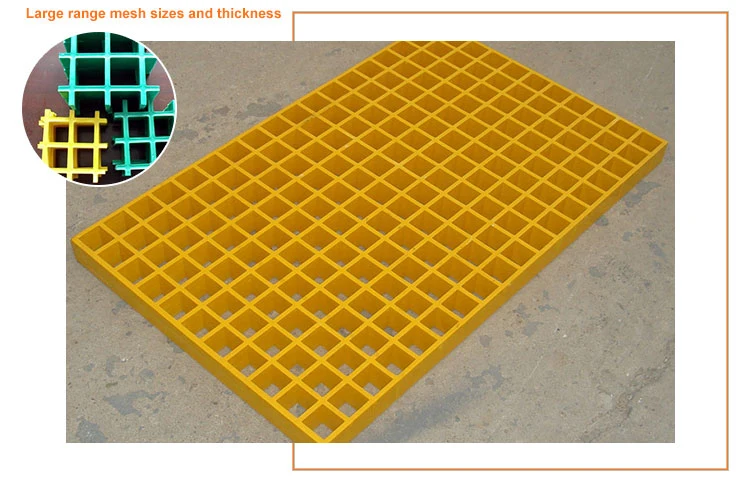

FRP Molded grating is manufactured by laying continuous glass fibres in the mould in the direction of vertical and horizontal, and thurougly wetted out with resin, layer by layer.Any process such as post applied grit could be bonded after as a secondary operation.This continuous process produces an integral, one piece panel,which offers excellent corrosion resistance as well as bi-directional strength.

Fiberglass Reinforced Plastic (FRP) is a plank shaped material cured in the matrix of unsaturated resins including isophthalic, orthophthalic, vinyl ester and phenolic, with reinforced frame of fiberglass roving through a special production process, with a certain rate of open meshes.

FRP Molded Grating is a structual panel which uses high-strength E-Glass roving as reinforcing material,thermosetting resin as matrix and then casted and formed in a special metal mold.It provides properties of light weight,high strength,corrosion resistance,fire resistance and anti-skid.FRP Molded Grating is widely used in oil industry,power engineering,water&waste water treatment,ocean survey as working floor,stair tread,trench cover,etc,and is an ideal loading frame for corrosion circumstances.Our product passes a whole series of well known third party tests with the fire and mechanical properties,and the product sells well all over the word and has a good reputation.

Fiberglass floor floor Gratingis available in a variety of resins, standard and custom colors, depths, panel sizes and mesh configurations, it is used for their high strength, corrosion resistance, light weight, long life and safety. All FRP grating is made to meet the highest international standards.

FRP molded grating surface options include a meniscus or integrally applied grit top, both of which offer superior, slip resistant footing. also has many advantages over steel grating for performance and cost effectiveness. With a much higher strength-to-weight ratio, molded fiberglass grating is easy to handle, making for quick installation.

| Material | Phthalic resin or iso-phthalic resin |

| Processing technology | Molded |

| Surface treatment | Flat, concave, grit cover, checkered plate |

| Color | Any international standard color |

| Fixing clips | SS316 material: C/L/M types |

Related Products

-

![700X700mm FRP/GRP Composite Square Manhole Cover with Pull Rings]()

700X700mm FRP/GRP Composite Square Manhole Cover with Pull Rings

-

![Heavy Duty Ductile Iron Hinged Airport Gully Grating F900]()

Heavy Duty Ductile Iron Hinged Airport Gully Grating F900

-

![Pipe Coupling, Ductile Iron Flexible Universal Coupling]()

Pipe Coupling, Ductile Iron Flexible Universal Coupling

-

![Stainless Steel Sanitary Sanitaire Food Grade Milk Pneumatic Vacuum Butterfly, Diaphragm, Safety Relief Valve, Non Return Check Ball Control Valve (JN-BV1001)]()

Stainless Steel Sanitary Sanitaire Food Grade Milk Pneumatic Vacuum Butterfly, Diaphragm, Safety Relief Valve, Non Return Check Ball Control Valve (JN-BV1001)