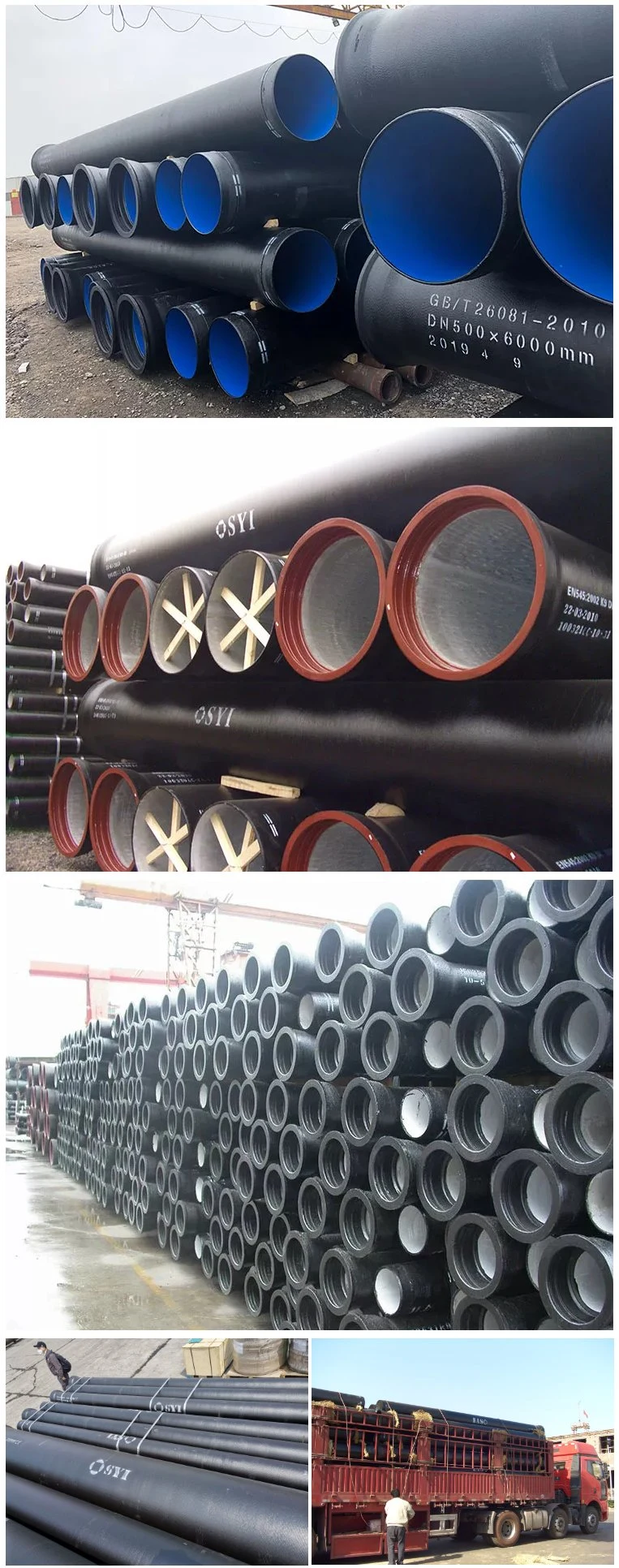

Syi ISO 10804 ISO 2531 En 545 En598 Centrifugal Cast Ductile Iron Restrained Joint Socket and Spigot Pipe

Centrifugal Cast Ductile Iron Restrained Joint Socket and Spigot Pipe ISO 10804 ISO 2531 EN 545 EN598 For Water Or Sewer

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | Restrained Joint Socket and Spigot Pipe |

| Customized | Customized |

| Gasket Material | NR |

| Product Name | Centrifugally Ductile Iron Pipe |

| Size | DN80 to DN2000 |

| Application | Pipeline, Water Supply, Drainage, Sewage |

| Processing Service | Cutting, Centrifugal Casting |

| Inside Coating | Cement Mortar Lining |

| Paint | Black Bitumen |

| Material | Ductile Iron |

| Pipe Wall Thickness | K7, K8, K9, K10,K12, K14, C20, C25, C30, C40, C50, |

| Transport Package | as Per Your Requirements |

| Specification | ISO 2531 EN 545 EN598 |

| Trademark | SYI |

| Origin | China |

| Production Capacity | 20000 Ton/ Month |

Product Description

Description

SYI can supply the Centrifugally Cast Ductile Iron Restrained Joint Socket and Spigot Pipe according to ISO 10804, ISO2531, EN545,EN598, from DN80 to DN2000, including K7, K8, K9, K10,K12, K14, C20, C25, C30, C40, C50, C64, C100, with the coating of Metallic Zinc (130-400g/m2), Zn-Al Alloy 85/15, Black Bitumen coating, Red/Blue Epoxy coating, Cement lining or PU (polyurethane) coating. Centrifugally Cast Ductile Iron Pipe is a kind of pipe made from spherical graphite cast iron by centrifugal spinning process. The pipes, which can convey many fluid media such as water, oil and gas, are widely used in various pipeline projects for metallurgy, mine, water conservancy, petroleum and urban public service utility.

| Nominal Size DN | Minimum tensile strength, Rm Mpa | Minimum 0.2% proof stress, Rp0.2 Mpa | Minimum elongation after fracture,A % | Hardness HB |

| 80-1000 | ≥420 | ≥300 | ≥10 | ≤230 |

| 1100-2600 | ≥7 | |||

| Note: 1. By agreement between manufacture and purchaser, the 0.2% proof stress (Rp0.2) may be measured. It shall be not less than: · 270 MPa when A≥12% for DN 40 to DN 1000 or A≥10% for DN >1000; · 300 MPa in other cases. 2. DN 40 to DN 1000, the minimum elongation after fracture shall be 7% for thickness classes over K12. | ||||

| Nominal Size(DN) | Hydrostatic works test pressure (bar) |

| 80-300 | 50 |

| 350-600 | 40 |

| 700-1000 | 32 |

| 1200-2000 | 25 |

| 2200-2600 | 18 |

| External coatings | Internal coating | Coating of the joint area |

| -Metallic zinc (130-400g/m2) -Zn-Al Alloy 85/15 -Black Bitumen coating -Red or Blue Epoxy coating | -Cement lining -Seal coat -PU coat | - Epoxy coating; - Polyurethane coating. |

Company

Related Products

-

![China Factory with CE/ISO En124 Ductile D400 Hinged SMC/BMC Square Fiberglass/Plastic/FRP Composite Manhole Cover Price for Resin]()

China Factory with CE/ISO En124 Ductile D400 Hinged SMC/BMC Square Fiberglass/Plastic/FRP Composite Manhole Cover Price for Resin

-

![China Epoxy Coated Ductile Cast Iron Flanged Pipe Fitting Manufacturer]()

China Epoxy Coated Ductile Cast Iron Flanged Pipe Fitting Manufacturer

-

![ISO2531 En545 En598 Class K7 K9 Water Pressure Ductile Iron Pipe Fitting]()

ISO2531 En545 En598 Class K7 K9 Water Pressure Ductile Iron Pipe Fitting

-

![Pipe Coupling, Ductile Iron Flexible Universal Coupling]()

Pipe Coupling, Ductile Iron Flexible Universal Coupling